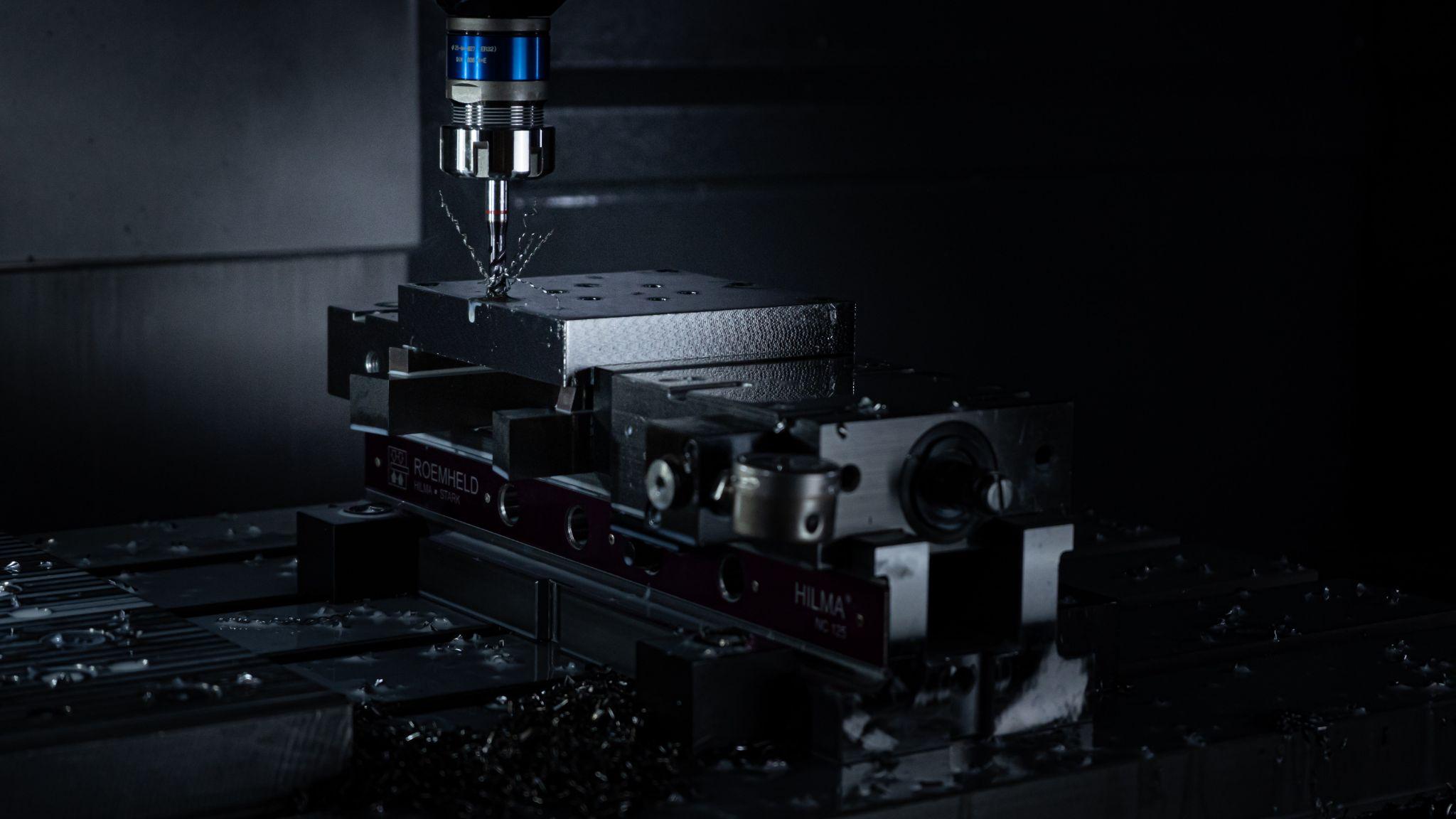

CNC machining, or computer numerical control machining, is a type of manufacturing process that uses equipment sets and numerical codes to create components. CNC machining has several advantages, including boosting the speed of component production and saving a significant amount of time when producing identical parts.

It also decreases the risk of human error during manufacturing because it’s entirely computer-controlled. CNC machining is also the most recommended manufacturing equipment to create precise or highly complex parts and components. CNC machines can produce objects made of various materials, including metals, alloys, and polymers. However, the expenses of using CNC to manufacture products are usually high and depend on multiple factors.

So, suppose you want to learn about the various factors that influence the cost of CNC machining. In that case, this post will discuss all of them and assist you in calculating CNC machining costs, and offer suggestions for how to lower them.

Costs Of CNC Machining

The cost of machining varies depending on multiple factors, such as the machine type. In that context, if you’re thinking about achieving maximum cost-efficiency when producing the next batch of your products, you might want to work with some of the best CNC machining services that utilize 3-axis CNC machines to manufacture parts.

At the end of the day, the cost of each machine is determined by elements such as the equipment’s size and configurations, power, and speed of the machine. For example, machining cost is computed per hour, and while a 3-axis CNC machining costs roughly $200 per hour, CNC turning machines cost around $350 per hour. On the other hand, CNC machining on multi-axis machines has a higher hourly rate, ranging between $400 and $600 per hour.

CNC machining is more expensive than other machining procedures because it involves more complicated pieces and tooling systems. As you can tell, the cost of machining increases as the number of axes on the milling machines increases. For example, in the instance of 5-axis machining, it is more expensive than 3-axis machines.

Quantity Costs

The cost of the final product is heavily influenced by the order volume. Certainly, the overall cost will rise as the number of finished components required rises, but the cost per part will fall.

Tolerances

Because fabricating parts with high tolerances necessitates complex machinery, the cost of producing products with tight tolerances will likewise rise. You may be required to make cavities or holes with tight tolerances, which may result in the formation of burrs on the surface, which will require additional time to remove.

Surface Finishing Cost

Surface finishing is necessary for various products, which raises the price of the final product. A good finish, such as polishing, may be required to improve the aesthetics of the finished product and erase any scratches generated during the machining process.

Blacking, anodizing, coating, chroming, brushing and water-transferring are some examples of other finishing procedures. The addition of any of these finishes to the final product will increase the price.

Dimensions And Complexity Of The Shape

The cost of machining increases as the complexity of CNC machined parts increases. Higher-complexity parts may necessitate additional process steps, different equipment, and longer production times.

The CNC machining cost increases by part feature such as sharp interior corners, deep voids, or thin walls. On the other hand, simple designs are simple to make and save time in the manufacturing process.

Components with more significant dimensions demand more raw materials and manufacturing time; hence, smaller parts will be higher.

Cost-Cutting Strategies For CNC machining

The cost of each CNC machining process is calculated before the start of the project. When using the CNC machining method to create parts, it’s important to keep the machining costs as low as possible. Some client-specific criteria cannot be changed, however, there are some ways to reduce machining costs, as follows:

Choose Your Materials Carefully

Special attention should be given to the selection of materials to lower the product’s cost, as process costs will be lower for materials with good mechanical characteristics. You must select the best material available that is simple to process while keeping the product’s function in mind. Metal and plastic materials differ in price. Of course, you can stick to your project’s requirements and rely on your manufacturer for material recommendations.

Quantity

If you need to create a big number of pieces, you can save a lot of money on machining. Because you only have to design the same part once, the cost per unit part will be lower. In this situation, you’ll have to redo the machine setup for each part, which will lower your production costs.

Optimization Of The Design

If some product characteristics aren’t critical to the product’s functionality, it’s best advised for the design to be simplified to avoid machining those elements, hence lowering production costs.

Final Thoughts

If you are concerned about the cost of CNC machining, you should consider all aspects that can affect the final price. But, remember, there are ways to lower the cost while maintaining a high-quality product. Many different methods affect the cost of CNC machining, and understanding them will help you make better decisions.